DTY Ambalaj made an investment in a fully automatic hot cellophane machine through Aysan.

DTY Ambalaj invests in KMM-D fully automatic paper laminator

Bayram Ulutürk (DTY Ambalaj): “Compared to our semi-automatic machine, setup time is much shorter, allowing faster job changeovers. The machine is also faster overall.”

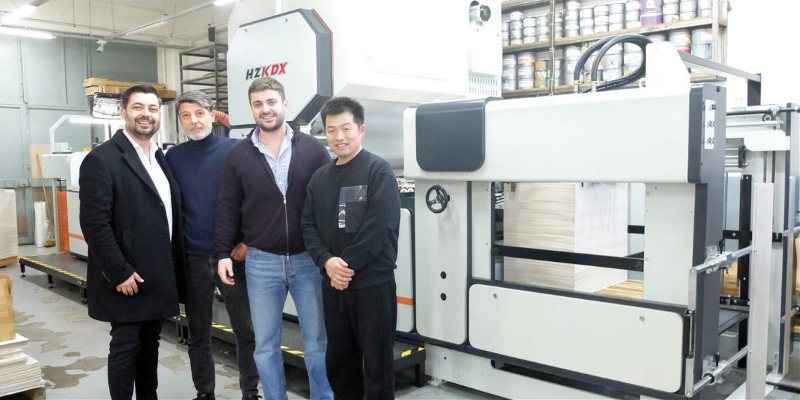

DTY Ambalaj Matbaacılık Ltd. Şti., operating from its 800 m² facility at Emintaş Matbaacılar Sitesi, Topkapı, Istanbul, with a 25-person team, purchased a KMM-D fully automatic sheet-to-sheet paper laminator (cellophane) from Aysan Matbaa Makine ve Malzemeleri Ltd. Şti. The single-sided laminator was installed in the first week of March and, following operator training by a technician from China, began production.

Bayram Ulutürk, third-generation manager of the family company, explained the background:

Company background

DTY Ambalaj was founded in 1990 by Bayram Ulutürk’s grandfather. Previously, the family ran a paper trading business under the name Başaran Kâğıt. Bayram’s father continued the business, and Bayram now manages it as the third generation. The company operates both printing and post-press machinery and works with a professional graphic team. Older machines are regularly upgraded.

Reason for cellophane machine investment

The company previously used a semi-automatic cold laminator and aimed to upgrade to a fully automatic hot laminator. Aysan has long supported DTY with materials, inks, cellophane, and printing chemicals, ensuring correct Pantone color matching and faster production. The KMM-D machine investment was guided and supported by Aysan, particularly by Kadir Babataş.

Sectors served

DTY produces cardboard boxes and bags primarily for cosmetics and food, with smaller quantities for textiles and toys. Cosmetic packaging emphasizes appearance and color accuracy, while food packaging requires hygienic production.

Machine performance

Bayram Ulutürk confirmed satisfaction with the machine’s speed. “Laminating follows printing. The fully automatic machine accelerates post-press processes. It supports upgrading our other post-press machines. We also have three cutting machines (automatic, pedal, and roller), a laminator, gluing machine, and foil-stamping machine.”

Export capacity

Primarily serving domestic clients, DTY also has some export capacity. Expansion in exports requires promotion and trade fair participation.

Advantages of hot vs. cold laminating

Cold laminating is not suitable for all jobs, especially for base layers, and may leave stains. Hot laminating with a fully automatic system reduces setup time, speeds up job changes, and prevents color issues in cosmetic packaging.

Future goals

DTY plans to expand exports, upgrade other post-press machines, and potentially replace their current 50×70 Komori press with a larger 70×100 5+Varnish press. Labor shortages necessitate newer technology machines, especially for exports where color precision is critical.

Technical details of the KMM-D machine

Kadir Babataş (Aysan) explained: “The machine has a 50% Italian-owned Synergy Group partnership, with Italian-made hot-knife components and Japanese sensor technology. The sheet-to-sheet machine complements the client’s existing roll-to-roll and thermal double-sided laminators.

Hot-knife rollers heat to cut without burrs, unlike metal-cable systems. While competitors heat with oil or water, KDX uses a patented electromagnetic system, heating 30% faster and consuming 25–30% less energy. These advantages place our clients ahead of competitors.

These machines are favored by contract laminators for 24-hour operation, quick setup, speed, and energy savings. Cold systems use ammonia, which can corrode inks and dull colors; hot laminating prevents color issues. DTY Ambalaj now operates one such machine; others have been installed in Ümit Matbaacılık (Istanbul) and Aydan Kutu (Ankara).

To date, 22 machines have been installed in Turkey, with eight installed after drupa 2024. Aysan supports customers continuously, regardless of warranty or failure frequency, providing additional confidence.”